Blade Width and Saw-Cut Loops

The using the right blade for the job can save you a lot of headache.

By Brian Dickson (www.bdloops.com)

Ever find yourself getting home late from a gate or door installation that took way more time to finish than it should have? Every installer is looking to reduce their gate and door installation times whenever possible, this can be done a number of different ways, all it takes is the correct tools and knowledge about the products being installed. One simple way installers can save a lot of time is by choosing the proper blade for cutting in saw-cut loops.

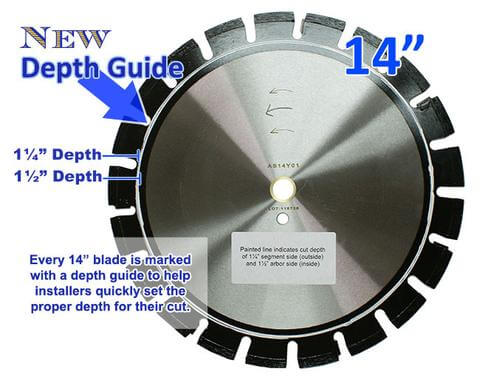

Before you start cutting, make sure you have the right blade selected for the job to help insure a functional gate or door system. Diamond blades are expensive and most installers don’t even know that there are professional grade blades designed specifically for cutting into asphalt or concrete. The advantage of using the correct pro blade for the application is a quicker cut and increased life of the saw blade (up to 3x as long). This is accomplished by the blades having a special bond which holds the diamonds, choosing which blade to use is dependent on the material you will be cutting into. For example, concrete surfaces are less abrasive than asphalt and require a softer bond for the diamonds. As the blade cuts the bond starts to wear which will reveal a new set of diamonds, essentially sharpening the blade while it cuts. If a blade with a hard bond is used in concrete the diamonds will wear and the blade will become glazed. When a blade is glazed it will stop cutting altogether. The blade will continue to be unusable until a new set of diamonds is revealed which can be done by running the blade through an abrasive surface such as asphalt. It is important to use the proper type of blade otherwise damage to the machine or blade could occur. The width of the blade will also affect how fast a groove can be cut, but there are some specific conditions to consider when deciding which sized blade to use.

BD Loops 3/16" Pro Diamond Blades 14" Diameter

$313.50

BDLoops durable 14" pro blades for all types of saw-cut applications

Select Combo, Concrete or Asphalt above.… Read More

It is amazing how just one small aspect of a saw-cut installation, such as blade width can be so crucial for the life of the loop you are installing. Many installers and wire suppliers recommend the use of a 1/8” saw blade for saw-cutting in loops. It is easy to understand why, 1/8” diamond blades are inexpensive, make a narrow cut, and are easy to find in stores, but 1/8” blades cause a lot of issues that installers cannot easily see and the benefits are not worth the consequences.

Do you find yourself repairing old saw-cut jobs often? Ever wonder why loop wire becomes exposed over time? Get repeat service calls from phantom trips or detector lock-up? Blade width is most likely the cause. 1/8” grooves are far too narrow to allow sealant to flow around 20AWG and 18AWG loop wire, if the wires are not fully encapsulated then it is very likely that air pockets will form.

Test data shows that even when using the thinnest two-component polyester loop sealer (epoxy) in a 1/8” groove there was not enough space between the wires and the saw-cut walls to allow the loop sealer to flow around the top wire and fill the void below, creating air pockets. Luckily preventing issues with air pockets is as easy as switching to a 3/16” or larger saw blade. Don’t let all your hard work go to waste, using a wider saw blade can make your loop installations less prone to failure. Protect your reputation and prevent the unneeded, and hard to diagnose service calls air pockets cause.

The width of the wire being installed will be the deciding factor of which size blade to use, the wire’s width is dependent on the gauge of wire and type of insulation it has. Wire used for loops commonly ranges from 18-14AWG. The best size blade to use with 18-16AWG wire is a 3/16” (.187) or larger blade. 3/16” or larger sized blades should be used when installing saw-cut loops to allow thick sealant to fully encapsulate the loop wire protecting the wires and preventing movement. If a smaller blade is used such as 1/8” (.125) there will not be enough clearance for sealant to flow around the wires and air-pockets will form. Using a 3/16” blade is preferred over a ¼” saw blade because 3/16” blade cost less it will put less bog on your saw-cut machine, and require 25% less loop sealant to fill than a ¼” groove. 3/16” blades in the past have been hard to find in our industry, but thanks to the efforts of BD Loops various types of Pro 3/16” blades are easy to purchase from any of their distributors.

Air pockets are an issue that plagues saw-cut loops run though narrow 1/8” grooves. If there is an air pocket in your loop, ground vibrations from cars, trains, or even the gate itself can cause the loop wires to move slightly and create false detections or detector lock-up. Air pockets allow space for water to pool in the groove and around the wire, which can cause the loop to short to ground while the wire is wet. If water gets into an air pocket and freezes it will expand causing the wires to be pushed to the surface, leaving the exposed wire vulnerable to tires or a snow plow blade. Air pockets can also be formed by the “coil back” effect of loops wrapped off of spools of wire which prevents sealant from fully encapsulating the wires.

“Coil back” describes the curved impression that is caused by wire being tightly wrapped around a wire spool. When wrapping a loop each individual conductor is supposed to lay flat, which is nearly impossible when a curved impression (coil back) is present. The “coil back” effect gets worse as the wire’s wrapped diameter on the spool decreases (as you get towards the end of the spool). Even with backer-rod every 1-2ft air pockets can still form. Another hard issue to get around when wrapping your own saw-cut loops is if the turns of wire are slightly different lengths (as little as 1/8” in length) severe air-pockets can form if the loop is shoved into a 1/8” groove.

The coil back effect is most noticeable in smaller gauge wires, such as 18 and 20 AWG. The insulation around the wires are thick compared to the amount of copper in the wire and maintain a strong memory from being wrapped around a small spool so they try to coil back up when you are wrapping a loop. There is so little copper in 18 and 20 AWG wires that even if you try to press the wire down, it will still coil back. The copper is not thick enough or strong enough to hold it in place. Smaller gauge wires have little tensile strength and are more prone to breaking when tension is applied. Larger (thinner) gauge wires do not distribute tension as well as lower (thicker) gauge wires. Overall lower (thicker) gauge wire is better to use because its overall performance increases and it becomes a more ideal inductor, in the wire industry this increase in performance in referred to the wire’s Q-factor.

Saving time can be as simple as choosing the proper blade for the job, look into investing in a pro asphalt, concrete or combo blade, they are well worth the expense. When cutting saw-cut grooves be sure to use a 3/16” or larger blade, don’t let all your hard work go to waste and allow your loop installation to be plagued with air pockets by using a 1/8” blade. Preventing air pockets from forming is an easy way to prevent repeat service calls which cost the installer money. Use a preformed loop with watertight soldered connections or take additional care when wrapping loops off a spool of wire to avoid “coil back” and shorts to ground. I encourage you to seek out manufactures and distributors to learn more about the tools you are using and always ask yourself and your crew: “How can this be done more efficiently?”

All credit to Brian Dickson at BD Loops.